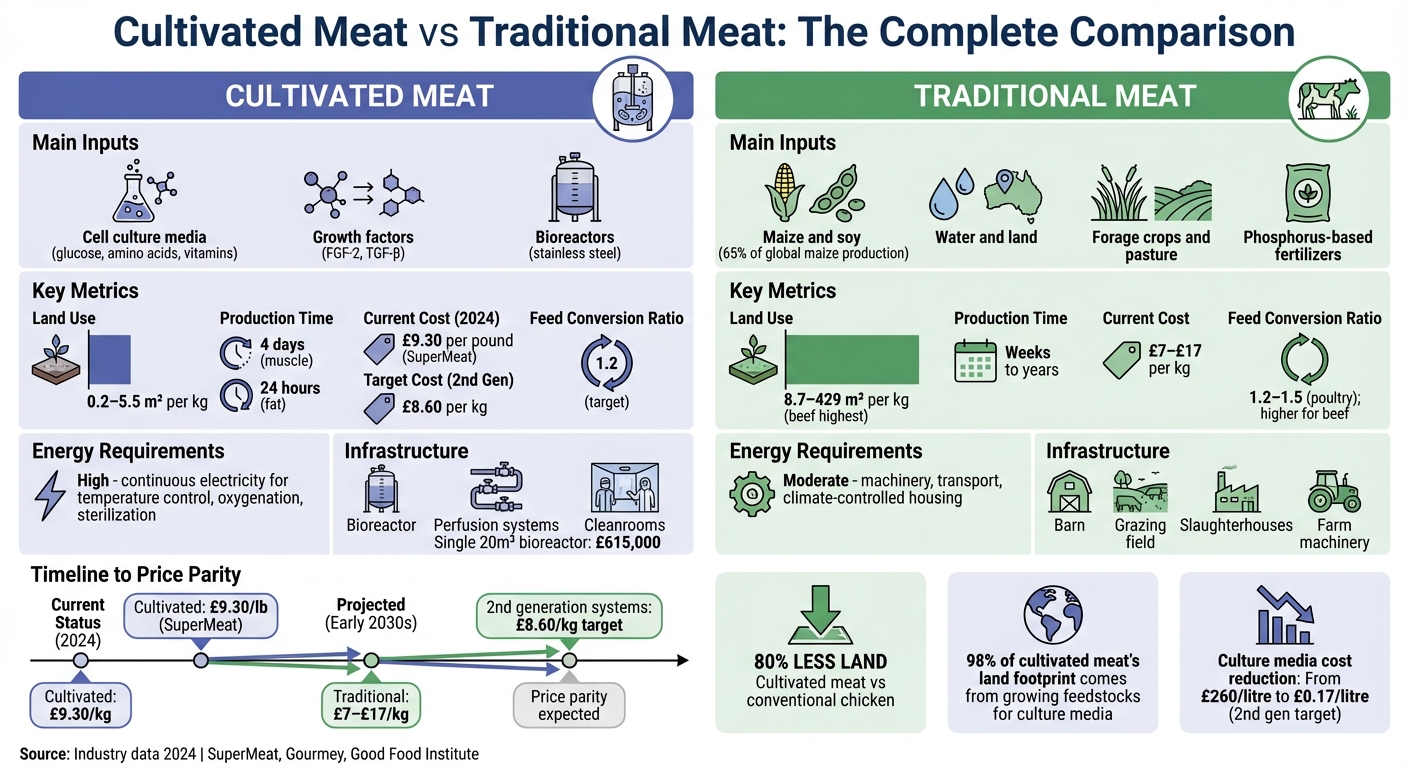

Cultivated meat is closing the gap on price, but raw material costs remain a challenge. Here's the key takeaway: cultivated meat relies on expensive cell culture media, while meat from farms depends on low-cost feed like maize and soy. The cost difference is narrowing as companies find cheaper alternatives for cultivated meat production.

- Cultivated Meat: Uses cell culture media (amino acids, glucose, vitamins, growth factors) and bioreactors. Costs are dropping, with some producers achieving £9.30 per pound in 2024. Second-generation systems aim for £8.60 per kilogram.

- Farmed Meat: Relies on crops (65% of global maize production), water, and land. Costs are lower, typically £7–£17 per kilogram, but rising due to land shortages and stricter regulations.

Quick Comparison

| Feature | Cultivated Meat | Farmed Meat |

|---|---|---|

| Main Inputs | Culture media (e.g., glucose) | Maize, soy, forage crops |

| Land Use (per kg) | 0.2–5.5 m² | 8.7–429 m² |

| Production Time | Days (muscle in ~4 days) | Weeks to years |

| Cost (2024) | £9.30 per pound (SuperMeat) | £7–£17 per kilogram |

Cultivated meat is advancing with cheaper media and efficient systems, while farmed meat faces increasing pressures. By the early 2030s, cultivated meat could reach supermarket shelves at prices similar to farmed meat.

Cultivated Meat vs Traditional Meat: Cost and Production Comparison 2024

Cost drivers of cultivated meat production

Raw Material Inputs: Cultivated Meat vs Traditional Meat

The ingredients needed to produce meat vary significantly depending on whether you're growing cells in a bioreactor or raising animals on a farm. Let’s dive into the specifics of each system and their impact on production costs.

What Cultivated Meat Production Requires

Cultivated meat relies heavily on cell culture media, a liquid mixture that feeds and supports cell growth. Key components include glucose (often derived from maize or starch), amino acids (typically sourced from soybean hydrolysate), and a carefully balanced mix of vitamins and salts [3][4]. This solution is meticulously designed to provide the ideal conditions for cells to thrive.

Another critical element is growth factors - proteins like fibroblast growth factor-2 (FGF-2) and transforming growth factor beta (TGF-β) - which guide cells to multiply and develop into muscle tissue [3][5]. A widely used formulation, Essential 8 Media, includes ingredients such as insulin, transferrin, selenium, ascorbic acid, and sodium bicarbonate [3].

"Cell culture media is currently the largest cost and environmental impact driver for cultivated meat production." – Good Food Institute [5]

The process also requires stainless steel bioreactors, made from materials like chromium and nickel, which maintain a steady temperature of 37°C while supplying oxygen to the growing cells [2][3]. A single 20 m³ food-grade bioreactor costs around $778,000 (approximately £615,000) [3]. These bioreactors must remain sterile, and the metabolic activity of billions of cells generates heat - about 470 kJ per mole of oxygen consumed - necessitating constant cooling systems [3].

Energy use is another significant factor. Bioreactors consume electricity for heating, cooling, oxygenation, and sterilisation, making energy demand a key consideration in the production process [2][3].

In essence, cultivated meat replaces the natural biological processes of animals with a highly controlled, industrial setup.

What Traditional Meat Production Requires

Traditional meat production, on the other hand, revolves around agricultural crops used as animal feed. Livestock farming consumes around 65% of the world's maize production, alongside soybeans, forage crops, and pasture [2]. Animals convert these feed sources into muscle, bone, and other tissues over months or even years.

This system requires large amounts of land, both for grazing and for growing feed crops. For instance, producing a kilogram of beef can require anywhere from 15 to 429 m² of land, depending on whether cattle are raised intensively or on pasture [6]. Land use represents one of the starkest contrasts between traditional and cultivated meat production.

Water is another essential input, used for both livestock hydration and irrigation of feed crops. Traditional farming also depends on phosphorus-based fertilisers, with livestock farming accounting for a significant share of global phosphorus use [2]. The infrastructure involved is relatively simple, including fencing, barns, slaughterhouses, and farm machinery, which typically run on diesel or petrol.

Unlike cultivated meat, traditional farming generates manure, a nitrogen-rich by-product that can be recycled as fertiliser for feed crops. This creates a degree of circularity in the system, though it also introduces challenges like nitrogen runoff and water pollution [6].

At its core, traditional meat production relies on natural biological processes - like digestion and metabolism - occurring within animals, while cultivated meat substitutes these with carefully engineered chemical and industrial processes. The differences in raw material needs highlight the contrasting approaches of these two methods.

Cost Comparison: Cultivated Meat vs Traditional Meat

The price gap between cultivated meat and traditional meat remains significant, but advancements are steadily closing this divide. By examining the key cost factors, we can better understand the economic hurdles and potential opportunities in this emerging industry.

Culture Media Costs vs Livestock Feed Costs

Culture media is currently the biggest expense in producing cultivated meat. Early systems, which rely on pharmaceutical-grade ingredients, can cost as much as €300 per litre (approximately £260 per litre) at a laboratory scale. This translates into finished products priced between €250–€300 per kilogram (roughly £215–£260 per kilogram), a stark contrast to traditional meat, which costs just €8–€20 per kilogram (about £7–£17 per kilogram) [4].

However, progress is being made. In November 2024, SuperMeat, an Israeli company, announced it had reduced production costs for 100% cultivated chicken to $11.79 per pound (about £9.30 per pound or £20.50 per kilogram). This was achieved by replacing costly animal-based serum and albumin with plant-based alternatives, bringing feed costs down to under $0.50 per litre (approximately £0.40 per litre) [1].

"Our new report provides proof that with the right technology there is a commercially viable path to market." – Ido Savir, CEO and Co-founder, SuperMeat [1]

Second-generation systems are aiming for even lower costs. By using media priced at just €0.20 per litre (around £0.17 per litre), producers hope to deliver cultivated meat for under €10 per kilogram (approximately £8.60 per kilogram) [4]. Gourmey, a Paris-based company, is working towards this goal at its €35 million (roughly £30 million) facility. Their approach includes continuous harvesting and protein-free media to achieve cost parity with traditional meat [4].

| Feature | Cultivated Meat (2nd Gen Target) | Traditional Livestock Feed |

|---|---|---|

| Primary Components | Amino acids, sugars, food-grade proteins [4] | Grains (maize, soy), forage, supplements |

| Cost per Unit | Target: £0.17/litre [4] | Much lower cost per kilogram |

| Feed Conversion Ratio | 1.2 (target) [4] | 1.2–1.5 (poultry); higher for beef/pork |

| Production Speed | Muscle in 4 days; fat in 24 hours [1] | ~42 days for traditional chicken |

Traditional feed relies on well-established crops like maize and soy, which are relatively inexpensive and stable in cost. Meanwhile, cultivated meat's feed conversion efficiency is inching closer to that of poultry farming, with second-generation systems targeting a ratio of 1.2 [4].

Energy and Infrastructure Costs

The energy requirements for cultivated meat production differ significantly from those of traditional farming. Cultivated meat production depends on continuous electricity to power bioreactor functions like temperature control, oxygenation, mixing, and sterilisation [6]. These processes demand more direct energy compared to traditional farming, where energy is primarily used for machinery, transport, and climate-controlled housing [6].

Infrastructure needs also vary. Traditional meat production relies on simpler setups like barns, grazing areas, and slaughterhouses. In contrast, cultivated meat production requires advanced facilities, including bioreactors, cleanrooms, and perfusion systems. To manage costs, companies are adopting modular "scale-out" strategies instead of building massive single reactors. For example, as of May 2025, Gourmey operates six 5,000-litre bioreactors (each with a 2,500-litre working volume) to mitigate contamination risks and optimise capital expenses. This modular approach recognises the diminishing returns of scaling up reactor sizes due to increased installation and maintenance costs [4].

| Feature | Cultivated Meat Infrastructure | Traditional Meat Infrastructure |

|---|---|---|

| Primary Assets | Bioreactors, perfusion systems, cleanrooms [4] | Barns, grazing land, slaughterhouses |

| Energy Demands | High (temperature control, oxygenation, stirring) [6] | Moderate (machinery, transport, climate control) [6] |

| Land Requirement | 0.2–5.5 m²/kg [6] | 8.7 m²/kg (poultry); up to 429 m²/kg (beef) [6] |

| Scalability Risk | Contamination, mixing issues in large reactors [4] | Disease outbreaks, weather dependency |

One of the clearest advantages of cultivated meat is its reduced land use. Producing cultivated meat requires up to 80% less land than conventional chicken farming [1]. Total land use ranges from 0.2 to 5.5 m² per kilogram for cultivated meat, compared to 15 to 429 m² per kilogram for beef [6]. Interestingly, 98% of cultivated meat's land footprint comes from growing feedstocks like maize and soy for culture media, with only 2% used for production facilities [6].

These cost dynamics offer valuable insights into the scalability and future potential for cost parity between cultivated and traditional meat.

sbb-itb-c323ed3

Scalability and Cost Parity Potential

When it comes to making cultivated meat a viable alternative to traditional options, scaling up production has become a game-changer. Thanks to new technologies, the costs of cultivated meat are inching closer to those of conventional meat.

How Cultivated Meat Costs Could Fall

The shift from outdated batch systems to more advanced continuous processes is at the heart of cutting raw material costs. Modern continuous perfusion systems can now run for over 60 days, allowing for a steady harvest of biomass while constantly replenishing nutrients and removing waste. This approach is far more efficient than the older batch cycles, which lasted just 1–3 weeks [4].

Another big leap is in replacing expensive pharmaceutical-grade growth factors with food-grade alternatives. Ingredients like rapeseed protein isolates, fermented okara, and microalgae extracts are helping to bring down media costs to around €0.20 per litre (approximately £0.17 per litre) [4]. On top of that, advancements in cell line engineering, such as suspension-tolerant cell lines with built-in autocrine signalling, are reducing the need for pricey external growth factors like FGF2 [4]. Computer models are also playing a key role, fine-tuning media formulations to avoid wasting expensive amino acids. Meanwhile, modular "scale-out" strategies - using multiple medium-sized bioreactors instead of one massive unit - are capturing up to 90% of the benefits of scaling up [4].

"The cultivated meat industry is approaching an inflection point. With rising global demand for protein, accelerating technological progress, and strong sustainability credentials, the foundations for success are in place." – Arthur D. Little [4]

In 2024, research led by Pasitka et al. showcased a continuous production method for cultivated chicken that hit a price of $6.20 per pound (roughly £4.90 per pound or £10.80 per kilogram), making it competitive with organic chicken [7]. These breakthroughs highlight how innovations in raw material use and production processes are positioning cultivated meat as a serious contender in the market.

Traditional Meat Cost Trends

Traditional meat production has long benefited from decades of agricultural refinement, with feed ingredients like maize and soy supported by robust supply chains and economies of scale. However, these advantages are increasingly offset by rising costs tied to environmental challenges. Issues such as deforestation, greenhouse gas emissions (which account for 14% of global totals), land shortages, water limitations, and stricter regulations are all driving up costs [8].

"If cultivated meat can be made to taste, feel, and look the same as traditional meat, at close to the same price, it has the potential to become one of the preferred substitutes for the meat from cows, pigs, sheep, goats, and chickens." – Khaled Tawfik, Partner, Boston Consulting Group [8]

While cultivated meat continues to see cost reductions through technological innovation, traditional meat faces mounting challenges. The real question is not just whether cultivated meat can match today’s prices, but whether traditional meat can keep its costs steady as environmental and regulatory pressures grow.

Conclusion

The cost of raw materials for cultivated meat compared to traditional meat boils down to their very different production systems. Traditional meat relies heavily on grain-based feed for livestock, significant land usage, and lengthy biological cycles. In contrast, cultivated meat can grow muscle tissue in mere days, thanks to its use of specially formulated culture media, controlled bioreactors, and rapid cell growth processes [1]. However, the current price disparity is largely due to the high cost of pharmaceutical-grade growth factors. That said, recent advancements are starting to shift this balance. Addressing these cost challenges is crucial for achieving price parity.

One promising example is a recent demonstration where cultivated chicken reached cost parity with premium pasture-raised chicken by replacing animal-based media components with plant-derived alternatives [1]. As production scales up and methods like continuous harvesting become more commonplace, the cost advantage of traditional meat is expected to diminish significantly.

These factors help explain why cultivated meat currently sits above the price of supermarket commodity meat. However, many forecasts predict broader price parity by the early 2030s [8]. Traditional meat is also under pressure, facing challenges such as rising feed costs, shrinking land availability, and stricter environmental regulations. Meanwhile, technological progress continues to lower the production costs of cultivated meat, reshaping the competitive landscape.

Ultimately, raw material costs are at the heart of pricing for both types of meat. For those curious about why cultivated meat costs what it does, Cultivated Meat Shop provides clear, science-backed insights into pricing, production methods, and the technological strides that are bringing cultivated meat closer to everyday affordability. As a trusted resource, it helps consumers understand not just what cultivated meat is, but also why its cost structure differs - and how that gap is narrowing faster than many might expect.

FAQs

What are the main factors influencing the cost of cultivated meat production?

The cost of producing cultivated meat largely hinges on the culture medium, which supplies the nutrients and growth signals essential for cell development. At present, the most expensive components of this medium are growth factors and recombinant proteins, which can make up as much as 90% of the total production costs. Reducing or finding alternatives to these pricey elements is a critical step towards making cultivated meat more accessible.

Another major expense comes from the bioreactor systems required for large-scale cell cultivation. These systems are costly to design, construct, and operate, as they must maintain precise conditions such as temperature, pH, and oxygen levels. Beyond the equipment itself, additional costs include energy use, labour, and post-production processes like harvesting the cells and formulating the final product.

The production method also plays a role in overall costs. Traditional batch-based systems tend to consume more resources, whereas newer continuous systems, which support ongoing cell growth over longer periods, show promise for reducing expenses. Together, these factors define the current pricing challenges associated with cultivated meat.

For those curious to learn more about these cost drivers and their influence on future pricing, the Cultivated Meat Shop provides resources that break down this cutting-edge food technology in an accessible way.

How does land use compare between cultivated meat and traditional meat production?

Cultivated meat production requires far less land compared to traditional livestock farming. In fact, projections suggest that a global shift to cultivated meat could slash land use by 83% by 2050. This means we’d only need about one-sixth of the cropland and pasture currently devoted to conventional meat production. Earlier studies back this up, showing land use reductions of 70–80% when compared to beef, pork, or chicken raised in intensive farming systems.

This dramatic decrease is achievable because cultivated meat is grown from cell cultures in bioreactors. Unlike conventional farming, it eliminates the need for grazing land, feed crops, and animal housing. By simplifying the production process, cultivated meat not only provides a more efficient way to produce protein but also frees up agricultural land for other uses. The Cultivated Meat Shop highlights this as just one of the many environmental advantages of this forward-thinking approach to sustainable food.

What innovations are making cultivated meat more affordable?

Advances in both technology and biology are driving down the cost of cultivated meat, edging it closer to matching the price of traditional meat. One major factor is the use of large-scale bioreactors, which can hold up to 100,000 litres. These allow for more efficient production, while automation is cutting labour costs - an expense that typically accounts for about 30% of total costs. Techniques like perfusion culture, a continuous production method, enable cells to be harvested repeatedly over several weeks. This not only boosts yields but also reduces the cost of growth media to as little as £0.17 per litre.

Progress in biology is equally transformative. Researchers have developed muscle cells capable of producing their own growth-promoting substances, reducing the need for costly additives. On top of that, newer production processes allow bioreactors to operate continuously for months, significantly improving efficiency compared to older batch-based systems. By incorporating sustainable methods - such as using crop by-products as nutrient sources - cultivated meat production is becoming not only less expensive but also kinder to the environment. Projections indicate that by the early 2030s, the price of cultivated chicken could fall to around £4.90 per kilogram.